10 Expert Secrets About Roll-Up Garage Door Maintenance

By Seacrest Garage Doors Co. – Lincoln, NE

If your roll-up garage door has ever jammed on a freezing morning, locking your car inside while you scramble to make it to work, you’re not alone. At Seacrest Garage Doors Co., we recently helped a Lincoln homeowner whose industrial roll-up door wouldn’t open due to corrosion and misalignment. After performing a quick site check, our technicians identified worn-out steel sheet panels and a faulty cam action device. Within hours, the rolling sheet door was operating smoothly again, with reinforced durability and a 10-year warranty on parts and labor.

Across the United States, garage doors open and close approximately 1,500 times per year on average. In high-use commercial applications, that number can be even higher, especially in warehouses, storage facilities, and logistics hubs where heavy-duty roll-up doors are used. Without regular inspection and maintenance, the moving components of your roll-up door, from the chain hoist and steel slats to the track rails and latch, can deteriorate, potentially leading to sudden failure and costly downtime.

Whether you’re managing a commercial address or maintaining your home’s steel garage door, proper care and scheduled maintenance checks are vital to ensure the door’s long-term operation, security, and efficiency. Here are ten expert insights we’ve gathered from years of experience servicing a wide range of roll-up garage doors in Lincoln, NE, and beyond.

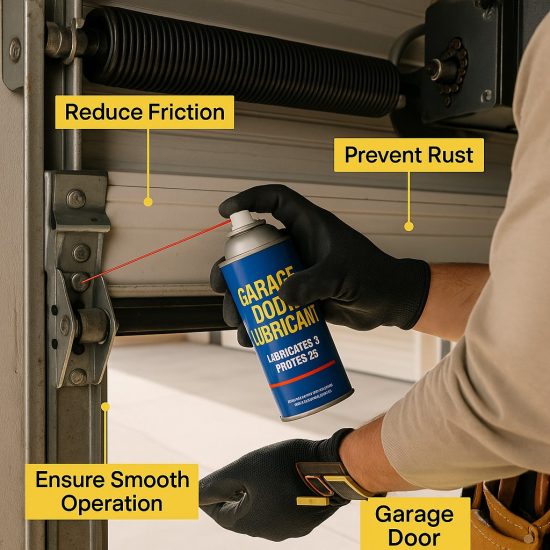

1. Lubrication Is a Game-Changer for Steel Longevity

Every roll-up door system, whether light-duty or heavy-duty, relies on multiple steel components, including chain systems, shaft bearings, and slat doors, that require regular lubrication. Use high-grade lithium grease or a Teflon-based lubricant on the chain, guide rails, spring barrel, and tension wheel. This protects against corrosion, especially in high-humidity sites like masonry garages or sheds.

Avoid over-lubricating, which can cause grit and dust buildup. Never use motor oil or general-purpose lubricants like WD-40; they degrade rubber seals and attract dirt, reducing the door’s life span and compromising wind load resistance.

2. Door Balance Affects Operation and Safety

When a roll-up garage door is not properly balanced, it puts stress on both the opener motor and internal spring systems. This can lead to uneven rolling, sudden slamming, or a misaligned latch. To test for balance, disconnect the chain hoist or motor and roll the door halfway up. If it slides down or resists movement, the internal spring tension needs adjustment.

Professional technicians can safely recalibrate the counterbalance system to meet commercial safety standards and local building codes. This is especially important for garage door models used in field applications or warehouses with varying door sizes (measured in square feet).

3. Clean the Rails, Tracks, and Roll Guides

Your roll-up door glides along vertical steel rails or guides that can collect dirt, metal shavings, leaves, and even small nesting insects over time. Regularly cleaning these components ensures quiet operation and prevents premature wear.

Use a soft brush and mild degreaser to remove buildup. Avoid water-based cleaners on doors with durable polyester paint or insulation, as it may damage protective coatings. For commercial roll-up doors, include the guide tracks and sheet overlap sections in every site check.

4. Watch for Rust and Corrosion, Especially on Slats

Lincoln’s changing weather from icy winters to humid summers means metal roll-up garage doors are exposed to the elements year-round. Inspect your door’s slats, hinges, and tension systems for signs of rust. In residential standards, light rust can be treated with a wire brush and rust-resistant primer.

For industrial or commercial door models, such as those using Janus model features or Amarr model features, severe rusting on steel panels may require partial panel replacement. Don’t ignore this corrosion weakens structural integrity and reduces certified wind load ratings per the International Building Code.

5. Check and Replace Weather Stripping and Bottom Bars

Weather stripping is more than a comfort feature; it protects against environmental controls like wind, pests, and flooding. Rubber or vinyl seals along the door bottom bar can degrade over time, especially on roll-up doors installed in high-traffic areas or exposed building sites.

Inspect for gaps or tears and replace with high-quality material rated for your local weather code, such as Lincoln’s wind and insulation requirements. Bottom bars with integrated latch systems should also be tested for secure sealing and manual locking operation.

6. Test Auto-Reverse and Safety Sensors

Safety sensors are a required feature in modern roll-up garage door installations. These sensors detect obstructions and prevent the door from closing on people, pets, or property. To test this system, place an object like a 2×4 board or roll of paper towels under the door and attempt to close it.

If the door doesn’t reverse immediately, the sensors may be dirty, misaligned, or damaged. Commercial codes and warranty terms often require this feature to be tested monthly. Doors without working auto-reverse sensors are a safety liability and can result in code violations on inspections.

7. Tighten and Inspect All Hardware Connections

Roll-up garage doors endure vibrations and repetitive motion, causing bolts, brackets, and chain connections to loosen over time. Check the door’s guide rail bolts, torsion spring mounts, and chain hoist anchor points twice a year.

Use torque specs outlined by the door’s manufacturer (e.g., Janus or Amarr) and verify against current standards like the Florida Building Code or International Building Code. For heavy-duty or wind-rated steel doors, this is critical for durability and warranty validation.

8. Replace Rollers and Tension Springs Before They Fail

Tension springs and rollers control how smoothly your roll-up door opens and closes. These components are under constant pressure and may fail after years of service. Look for signs such as uneven motion, grinding sounds, or gaps between slats during operation.

Spring and roller replacement is a key part of roll-up garage door maintenance for both residential and industrial door models. Avoid delays; failure to replace aging springs in time can lead to costly damage or unsafe conditions.

9. Inspect and Maintain the Opener System

Whether your door uses a motorized chain hoist, jackshaft opener, or wall-mount opener, regular inspections are essential. Ensure the drive carriage moves freely, the drive chain is tight, and all controls function properly.

For commercial applications, install smart openers that offer remote monitoring, auto-close features, and easy adjustment of force limits. Be sure to check compatibility with the garage door model, opener type, and duty cycle for your specific site.

10. Schedule Annual Site Checks and Professional Inspections

Professional inspections go beyond what most property owners can perform themselves. At Seacrest Garage Doors Co., our experts assess the full operation of your roll-up door, checking insulation, duty rating, latch function, certified wind load, and more.

Whether you have a light-duty rolling sheet door on a residential shed or a heavy-duty industrial steel door on a commercial address, scheduled inspections prevent downtime, extend the lifespan of your product, and ensure code compliance.

How Can Seacrest Garage Doors Co. Help You?

At Seacrest Garage Doors Co., we provide expert installation, repair, and maintenance for roll-up garage doors throughout Lincoln, NE, and the surrounding areas. Whether your system includes durable polyester paint finishes, certified wind load panels, or economical alternatives for residential use, we have the training and tools to handle any project.

📍Visit us at 6891 A St #104, Lincoln, NE 68510

📞Call today at (402) 374-9880

From chain hoists and latch systems to insulation, building code compliance, and custom color options, we’re your go-to partner for reliable, professional service. Contact us now to schedule your annual maintenance, request an inspection, or get a quote on a new installation.

Frequently Asked Questions (FAQs)

1. How often should I replace the tension springs on my roll-up garage door?

Every 5–7 years is typical, depending on usage frequency and spring type.

2. Can roll-up garage doors be insulated for better energy efficiency?

Yes, many models offer insulation options like polystyrene or polyurethane for climate control and noise reduction.

3. Are roll-up garage doors suitable for windy areas like Nebraska?

Yes, certified wind load-rated models that meet the International or Florida Building Code are ideal for such climates.

4. What is the difference between rolling sheet doors and slat doors?

Rolling sheet doors are made of one continuous steel sheet, while slat doors consist of interlocking metal slats. Slat models offer better flexibility and higher durability in commercial applications.